品牌名称:深圳市博尚微科技有限公司

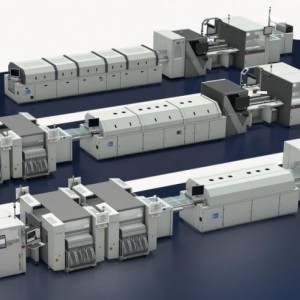

VXC nitro 3.5 (734)

VXC 734N, 10温区氮气回流焊

Reflow Soldering with Convection

Diversity with the VisionXC

多样化VisionXC回流焊接系统

Whether laptop, smartphone or in-car control systems – almost every technical end product contains sensitive electronics. The contacting of the electrical components on the circuit board using high-quality soldering is crucial when it comes to guaranteeing smooth function. Rehm Thermal Systems works to develop reflow soldering systems for your production which can be integrated seamlessly into the manufacturing environment.

Systematically applied technology and superb construction are the features of our convection reflow soldering systems. In the VisionXC the soldering process is performed on the basis of convection – that is, the transfer of heat via a flow of gases. Our systems are available in air or nitrogen versions. As an inert, protective gas, nitrogen is the ideal heat transfer medium and prevents disturbing oxidation during the soldering process. The modular system configuration of the VisionXC also offers a high level of flexibility for your production facility.

无论是笔记本、智能手机还是车载控制系统,几乎每一项科技产品都离不开敏感电子元器件,而通过高质量 焊接制程保证电路板上元器件的良好接触性对确保科技产品正常工作至关重要。因此,锐德致力于为客户打 造高品质回流焊接系统。

锐德VisionXC回流焊系统技术成熟、做工一流,采用对流式设计,通过气流传导热量 — 空气或氮气两种类型 可选。作为一种惰性保护气体,氮气是最理想的热传导介质,还能够在焊接过程中防止发生氧化。模块化设 计可以为您的生产线提供最高应用灵活性。

VisionXC

As individual as your production

符合个性化生产需求

Does your production environment need a compact system which can be adapted optimally to your requirements? Do you process sensitive electronic components which need to correspond to certain temperature conditions? We have a diverse range of system lengths!

您是否需要可精确匹配您个性化生产需求的焊接系统?您是否需要在特定温度下处理敏感电子元器件?我们可以满足您的所有需 求,为您提供多种个性化系统解决方案。

锐德创新解决方案 适用于多种制程应用

Your production department can meet any requirement using manufacturing equipment from Rehm!

With the VisionXC we offer different systems for optimum soldering processes in the most diverse of manufacturing environments. Different process zone lengths are available depending on the type of system. The pre-heating, peak and cooling zones have the same pitch and therefore are constructed in a modular design. Additional optional features can be added to the system concept seamlessly.

选择锐德,满足您的所有应用需求!

VisionXC可以针对不同生产环境和生产条件提供解决方案,实现焊接制程。根据系统类型,您可以选择不 同长度的制程区。此外,预热区、高温区和冷却区拥有相同的节距,支持模块化配置和部署。多样化的功能选项可 以满足您的不同应用需求。

Modular, flexible system concept

模块化灵活系统

Energy efficient system with lowest CO2 emission

节能高效,最低二氧化碳排放

Highest process stability even with lead-free soldering

稳定的无铅焊接制程

Minimum downtime and lowest maintenance effort

最低停机时间和维护需求

Excellent traceability due to smart software tools

智能软件工具,提供最高可追溯性

Lowest "Total Cost of Ownership“

最低“总拥有成本”

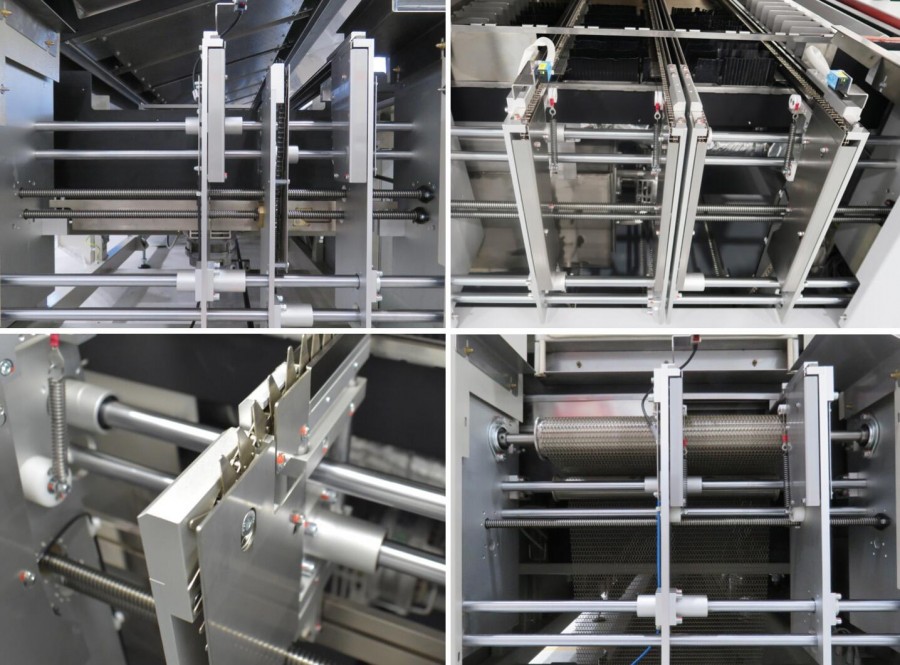

Reliable from A to B

with Flexible Transport Systems

灵活可靠的传输系统

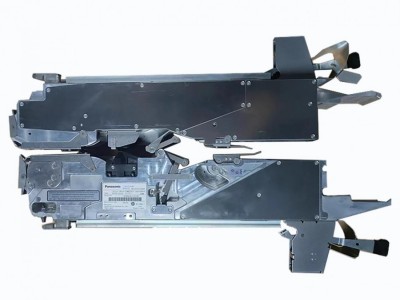

Your component will run through various sections of the system during the soldering pro- cess: from the preheating zone, through the peak zone to the cooling zone. Secure transpor- tation is a key entity when it comes to continuous processes. Rehm offers flexible systems for this.

Our transport systems provide the perfect fit for your components regardless of the circuit board geometry. Transport lanes and speeds are variably adjustable and enable parallel sol- dering processes with synchronous/asynchronous in one reflow system. Depending on the product requirements, you can choose from various transport models such as individual and double track transport, quadruple or multi-track transport, even mesh-belt transport.

The optional centre support enables even the processing of large circuit boards or boards with a flexible base material with ease and prevents any sagging during the reflow soldering, thus guaranteeing a maximum degree of process stability.

在焊接过程中,电子元器件将依次通过系统的各个区域:从预热区经过高温区再到冷却区。对连续制程 而言,安全的组件传输尤为重要。因此,我们为您提供了一套高度灵活的传输系统。 我们的传输系统可以不受电路板几何形状的影响,完美匹配您的组件。此外,传输轨道和传输速度都灵 活可调,可以在一个回流焊系统中实现并行双轨焊接(同步/异步)。根据具体需求,您可以选择不同的 传输模式,例如单轨和双轨传输、四轨或多轨传输,以及网带传输系统。 在焊接大型电路板或柔性基材时,中央支撑系统选项可防止组件发生形变,确保最高制程稳定性。

Reliable, failure-free production guaranteed by absolutely parallel transport

并行传输,实现可靠的无故障生产

Precise and repeatable adjustment of the transport width

传输宽度精确可调

No influence of the temperature profile by transport or center board support

温度曲线不受传输系统或中央支撑系统影响

Reduced maintenance, transport drive mechanism is outside of the process chamber

传输系统驱动机构位于炉膛外,维护需求极低

Ideal for any application due to various transport systems

多种传输系统可选,适合所有应用

High process reliability by integrated center board support

集成中央支撑板,具有最高制程可靠性

Separately adjustable heating zones

单独可调的加热区

Reproducible temperature profile

高重复精度的温度曲线

Homogenous heat transfer

4

Outstanding process stability with the smallest possible ΔT

出色的制程稳定性,最小ΔT

Homogenous heat input over the entire PCB thanks to specially designed nozzles

采用特殊设计的喷嘴,对整个PCB板均匀加热

Low maintenance effort

低维护需求

From Zero to 240 °C

due to optimized heat transfer

均匀的热传导性能

Each product has its own requirements in the manufacturing process. Optimized heat transfer over the entire soldering process is the basis for best possible results.

The VisionXC offers flexibly controllable preheat- ing zones within which your PCB is preheated and prepared for the actual soldering process. The in- dividual zones can be controlled independently of each other via fan frequency, and assure best pos- sible processes.

The VisionXC is equipped with special nozzle sheets for optimized heat transfer by means of uniform air flow over the PCBs. Flow speeds in the upper and lower heat zones can be separate- ly controlled, assuring that your PCB is heated up

through and through – completely and uniformly. This prevents stressing of the material which can disturb the soldering process. In addition, smaller componants are not overheated and bigger ones are still heated through enough.

To ensure that the heat flow in the system runs stably and the outward heat radiation is as low as possible, our VisionXC systems have optimum insulation between the process chamber and the exterior wall.

Using precise profiling we can generate preci- sion-reproducible temperature profiles which are tailored to component size, material or process parameters.

尽管不同产品具有不同的制程需求,但是,热传导 是所有产品实现出色焊接效果的基础。 VisionXC系列回流焊系统配备了可灵活调节的预热区,用 于对PCB板进行预加热,使其达到实际焊接所需温度。此 外,系统的各个区域均可通过调节风机频率进行独立控 制,确保达到效果。 VisionXC配备了特殊的整流板,可确保气流均匀地通过 PCB板,实现热传导。另外,您还可以分别调节顶部 材料应力对焊接制程产生干扰,同时确保小型部件不 会过热,大型部件得到足够彻底的加热。 为使系统中气流稳定,降低向外的热辐射, Vi- sionXC在炉膛和外壁之间采取了隔热措施。 通过制定精确、可重现的温度曲线,我们的系统可完美 契合您的制程要求,匹配您的组件尺寸、材质和其他制 程参数。

清洁型解决方案:

高效的残渣管理

As is the case with all industrial processes, substances are generated during SMT production which have to be removed from the process cycle because they contaminate the system. Our highly effective residue management function purifies the process gas safely and reliably, and keeps your system clean and dry.

和所有工业制程一样,SMT生产线同样也会产生可能污染系统的残渣,因此必须及时将 残渣从制程循环中排出。我们的高效残渣管理系统可以安全、可靠的净化制程气体,保 持系统洁净、干燥。

高效清洁,保证炉膛清洁、干燥

System integrated solution

一体化系统解决方案

Reliable, stable process

可靠、稳定制程

Easy accessibility

易于操作

Low maintenance effort

低维护需求

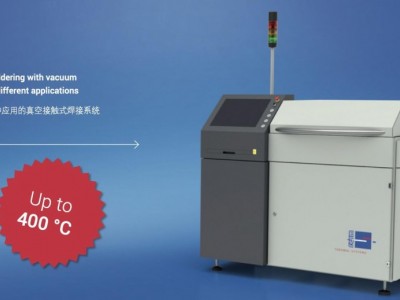

Stress-free to below 50 °C

with powerful cooling systems

无应力冷却至50°C以下

性能强劲的冷却系统

It is important to have a high-performance cooling tract in order to guarantee optimum sol- dering results and ensure that modules are cooled gently.

Rehm Thermal Systems offers a wide range of cooling tract variants for reflow convection soldering with its VisionXC, which can be precisely fine-tuned to suit any production process. The water-cooled standard solution with heat exchanger and adjustable ventilation system works as an effective "Closed Loop" system. There are several efficient, additional options for large and high-mass boards, primarily a bottom cooling system.

为获得焊接结果以及组件得到平缓冷却,需配备高性能冷却系统。

锐德为VisionXC提供了多种冷却系统,并支持精确微调以适应个性化生产制程。带热交换器和可调通风系 统的标准水冷解决方案可作为“闭环”系统,实现高效冷却。对于大型高密度PCB板,您可以选装底部冷却 系统。

Stress-free cooling using individually adjustable ventilators in the classic cooling zone

利用冷却区中多个可单独调节的风机实现无应力冷却

Optimum cooling of large, high-mass boards thanks to additional bottom cooling

提供底部冷却系统选件,完美冷却大型、高密度组件

Flexible combination possibilities through a range of different options

多种冷却选项。支持灵活配置

New, sustainable cooling principle as a result of liquid nitrogen cooling

创新型可持续液氮冷却技术

Intuitive software operation with touch-screen surface

带触摸屏的直观软件操作

Clear product management with offline programming

支持离线编程的清晰产品管理

Parameter transparency through module groupings

通过模块分组,实现参数透明

Easy adaption due to favourites bar

收藏栏,轻松适应不同制程

Multilingual software

多语言支持

深圳市博尚微科技有限公司

进入公司首页博尚2008成立香港,港資企業,為了提供中國客戶更快速的服務,並成立了華南子公司(深圳),華東子公司(蘇州)。為中國及國際客戶提供更便捷優質的服務。博尚是專業SMT整體解決方案供應商,主要代理日本Panasonic ,表面貼裝設備及其配件、韓國Pemtron SPI AOI ,德國REHM回流焊等及其配件,直銷美國ADI ,TI 電子集成電路。博尚骨幹成員在SMT行業具有十年以上的工作經驗,銷售及售後團隊均為八年以上售後服務經驗人員組成,面對國內客戶需求提供專業技術咨詢及完善的售後服務,加上一流的質量管理技巧,獲得眾多客戶的肯定。我們堅持以專業...

查看更多 >-

[诚信档案]

[诚信档案]

-

联系人:李志达(先生)

- 会员: [当前离线] [加为商友] [发送信件]

- 电话:

- 地区:广东-深圳市-光明区

- 地址:深圳市光明区观光路邦凯科技园4栋A座2001

深圳市博尚微科技有限公司

来电时请说是 国际能源网 看到的

-

面议

立即询价 -

面议

立即询价 -

立即询价