本公司其它产品

品牌名称:

Product Introduction

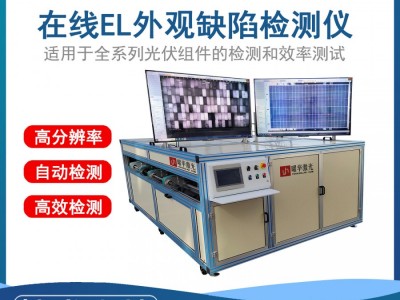

The PV Module EL Visual Defect Tester is an automated device integrating electroluminescence (EL) detection and visible light visual inspection functions. By applying current to energized modules in a darkroom to stimulate internal luminescence, it uses high-sensitivity cameras to capture EL images and simultaneously collect visible light images of the module surface. This enables intelligent identification, localization, and analysis of internal defects such as microcracks, fragments, grid breaks, cold solder joints, black chips, and contamination, as well as surface issues including scratches, edge chipping, dirt, color deviation, foreign objects, poor encapsulation, cell damage, and ribbon misalignment. It is a key testing equipment for realizing full-process quality control and reliability assurance of PV modules.

Product Features

Integrates dual functions of electroluminescence (EL) detection and visible light visual inspection. It can not only identify micro-internal defects such as microcracks, fragments, grid breaks, cold solder joints, and black chips but also detect surface flaws like scratches, edge chipping, dirt, color deviation, foreign objects, poor encapsulation, and ribbon misalignment, achieving integrated testing.

Adopts high-precision cameras to capture EL luminescence images of energized modules in a darkroom environment. Combined with advanced image processing and AI intelligent algorithms, it automatically completes defect identification, localization, classification, and analysis, significantly improving detection efficiency and accuracy while reducing manual dependence.

Features millisecond-level image acquisition and processing speed. Cooperated with automated assembly line design, it supports online high-speed detection, meeting the high-throughput and fast-paced quality control requirements of PV module production lines, and ensuring production efficiency and product yield.

Provides clear and intuitive defect reports and visualized data, offering reliable basis for process improvement and quality traceability. It is an indispensable core quality control equipment for ensuring long-term reliability of PV modules and enhancing product competitiveness.

Technical Parameters

| Item | Specification |

|---|---|

| Model | YH-EL8 |

| Applicable Processes | Defect detection of modules before and after lamination |

| Test Specifications | Various monocrystalline and polycrystalline solar modules |

| Camera Type | Professional industrial camera |

| Resolution | EL: 60 million pixels; Visual: 240 million pixels |

| Shooting Mode | 8-camera area scan mode |

| Sensitivity | Capable of detecting cracks with width < 0.03mm |

| Loading Method | Automatic loading and unloading |

| Detection Method | Online automatic detection |

| Effective Test Area | 2600*1500mm |

| Regulated Power Supply | 60V/20A |

| Image Acquisition Time | 100~700ms |

| Power Supply | 220V/50HZ |

| Equipment Dimensions | 3095×2220×1665mm |

Product Applications

Online Quality Inspection in Production Lines: Integrated at the end of PV module automated production lines, it performs high-speed, fully automatic EL and visual defect detection on newly encapsulated modules. It is a core link to ensure the quality of delivered products and control production yield.

Laboratory Precision Analysis: Applied in laboratories of manufacturing enterprises or third-party testing institutions, it conducts in-depth and accurate defect diagnosis, process effect evaluation, and failure analysis on raw materials (such as solar cells), process samples, and finished modules.

Power Plant Operation and Maintenance & Diagnosis: Through (usually portable or mobile) EL testing equipment, on-site quality inspection, performance evaluation, and fault diagnosis are carried out during the construction period (inspecting installation damage) and operation period (locating faulty modules with hot spots, microcracks, PID, etc.) of solar power plants.

R&D and Certification Testing: Serves R&D institutions and certification testing organizations of modules. It provides key defect detection and quality evaluation data during new product development, new material/new process verification, long-term reliability research (such as comparison before and after aging tests), and meeting the requirements of standard certifications such as IEC/UL.

Precautions

Current Operation Warning: The equipment applies DC current to modules during operation. Operators must strictly follow operating procedures, wear insulating equipment, ensure reliable grounding of the equipment, and are prohibited from touching electrodes or live parts of modules when energized to prevent electric shock accidents.

Darkroom Environment Guarantee: EL detection must be performed in a completely light-tight darkroom or closed cavity. Any external light sources (including indicator lights, mobile phone screen light) may interfere with EL images, leading to false detection or missed detection. Ensure environmental tightness before testing.

Standardized Module Handling and Placement: Large modules (especially bifacial modules) are heavy and fragile. When transporting and placing them on the test platform, handle with care and position accurately to avoid module damage or damage to equipment platforms/probes caused by collision or falling.

Optical System Maintenance: Regularly clean and maintain optical components such as high-sensitivity camera lenses, light sources, and reflectors (using professional tools and cleaning agents) to prevent dust, stains, and fingerprints from affecting imaging clarity and detection accuracy. Avoid direct strong light exposure to the lens.

Software Calibration and Parameter Setting: Appropriate current and voltage parameters, exposure time, and image processing algorithm thresholds should be set for modules of different models and powers. Perform regular software calibration (such as dark field calibration, flat field calibration) to ensure the accuracy and consistency of image quality and defect judgment.

Equipment Compatibility and After-sales Requirements: Before use, confirm that the equipment is compatible with the size, electrical performance parameters, and connector type of the modules to be tested. Strictly follow the manufacturer's manual for installation, operation, and maintenance. For key component repair or software upgrade, contact professional after-sales personnel to avoid equipment failure or warranty invalidation caused by unauthorized disassembly.

-

面议

立即询价 -

面议

立即询价 -

面议

立即询价